Quality

Ensuring Excellence at Every Turn

At Load Controls, our commitment to delivering unparalleled quality is not just a promise but a meticulously crafted policy embedded in our organizational DNA. We proudly hold certifications for our Integrated Management System, showcasing our adherence to the highest standards.

Certified for QMS (ISO 9001:2015), EMS (ISO 14001:2015), and OH&SMS (ISO 45001:2018), we operate within a framework that places quality, environmental responsibility, and occupational health and safety at the core of our operations.

To uphold our quality standards, we invest in our greatest asset — our team! Comprehensive training programs are a cornerstone of our approach, equipping every team member with the knowledge and skills required to maintain consistency in product quality and performance.

By fostering a culture of continuous learning and improvement, we empower our workforce to embrace evolving industry standards and deliver products that stand the test of time.

At Load Controls, quality isn’t a checkbox; it’s a philosophy that permeates every facet of our operations. Trust us for quality that goes beyond certifications — a commitment ingrained in our every endeavor.

Ensuring Uncompromised Quality Every Step of the Way

At Load Controls, quality is a culture ingrained in every stage of our operations. Our meticulous processes and unwavering commitment define our pursuit of excellence.

Stringent Checklist Culture:

From inception to delivery, we adhere to a strict checklist culture that leaves no room for compromise. At every stage of the manufacturing and operational processes, meticulous checks and balances ensure that our products meet the highest standards of quality and reliability.

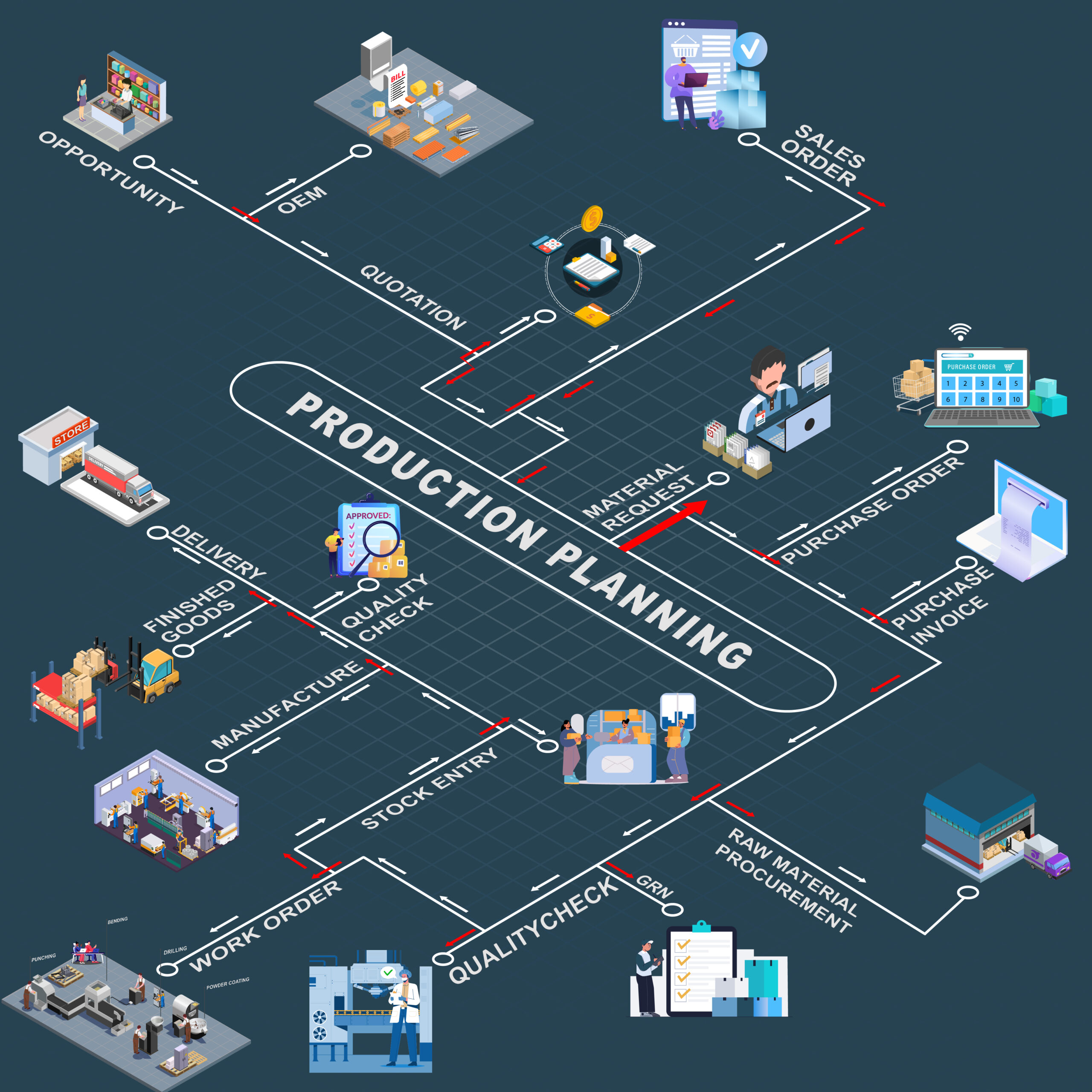

Streamlined Process Flow with ERP System:

Our operations are powered by a streamlined process flow, systematically managed through an Enterprise Resource Planning (ERP) system. The system orchestrates our operations seamlessly, minimizing errors, optimizing efficiency, and ensuring consistency across every department.

ERP Process Flow:

Our ERP system follows a structured process flow that guides our operations from inception to delivery:

1. Sales Opportunity: Opportunities are identified and assessed, laying the groundwork for potential sales.

2. Bill of Materials: Detailed lists of components and raw materials are compiled, ensuring clarity and precision in the manufacturing process.

3. Quotation: Accurate quotations are generated, reflecting the specific requirements and expectations of our customers.

4. Sales Order: Once confirmed, sales orders trigger a series of actions that set our manufacturing and procurement processes in motion.

Seamless Coordination Between Teams:

Upon receiving a sales order, our system seamlessly coordinates between departments, generating work orders for our manufacturing team and purchase orders for our store and procurement team. This ensures alignment, clarity, and efficiency in our operations.

Rigorous Quality Testing:

Our commitment to quality extends to the final stages of production. Before shipment, every finished product undergoes rigorous testing and inspection by our dedicated quality team. Only products that meet our stringent requirements and specifications are deemed ready for delivery to our valued customers.

Load Controls promises to uphold the highest standards of quality with every product we deliver. With our unwavering dedication to excellence and our meticulous approach to quality assurance, we ensure that every switchboard that bears our name is a testament to our commitment to superior craftsmanship and reliability.